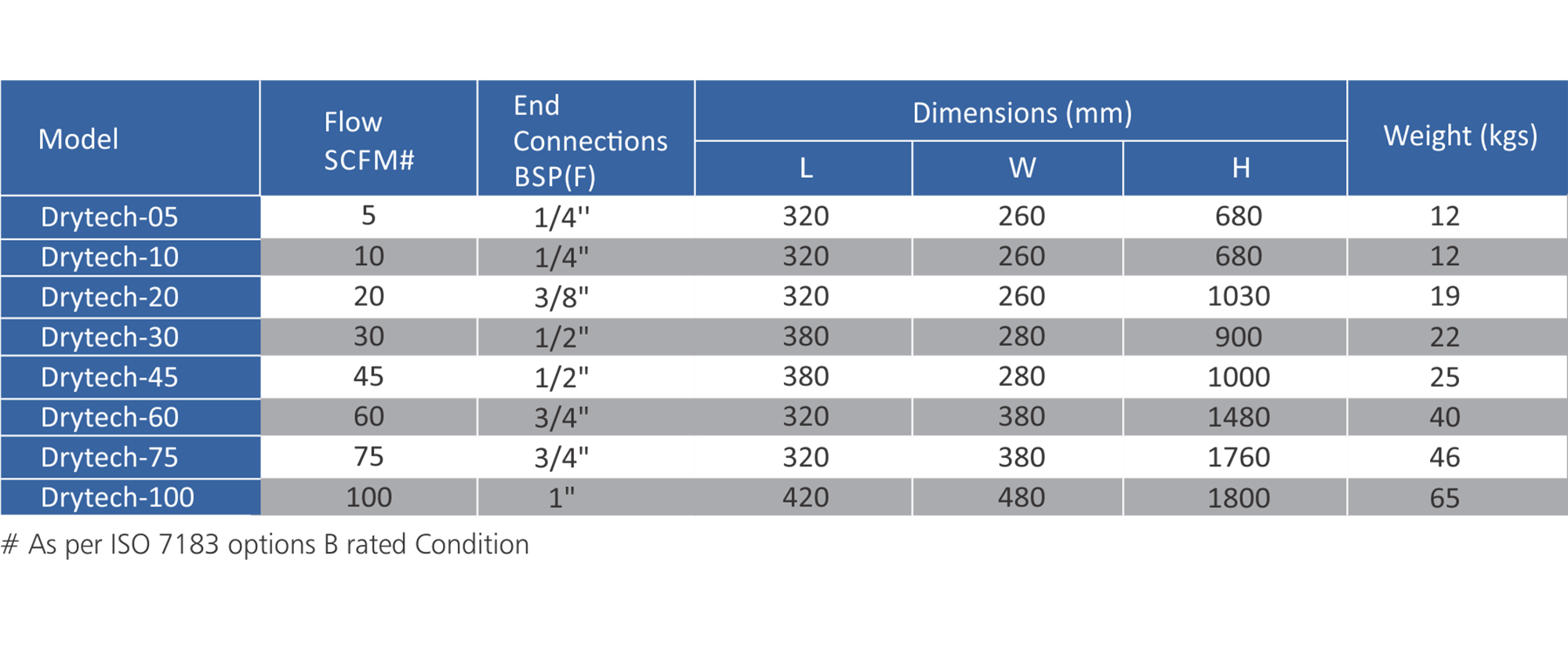

design paramerer : 100% RH, Inlet Temp. 40°C Operating Pr. 16 Max.

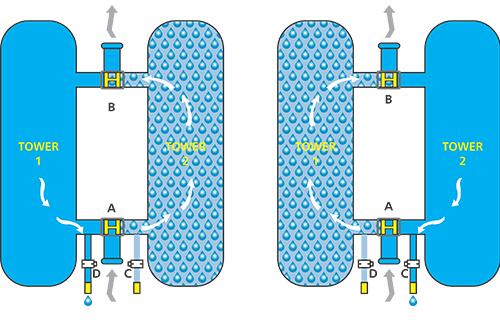

working principle :

Regenerative Desiccant Compressed Air Dryers are an economical process to reduce the moisture content of the compressed air to achieve the dew point as low as minus 40°C. The dry Compressed Air (at consistent) dew point is continuously achieved by using Twin Towers packed with desiccant. While one tower is on-stream- drying the compressed air, passing small percentage of dry air is regenerating the other. The cycle is repeated at per-set interval.