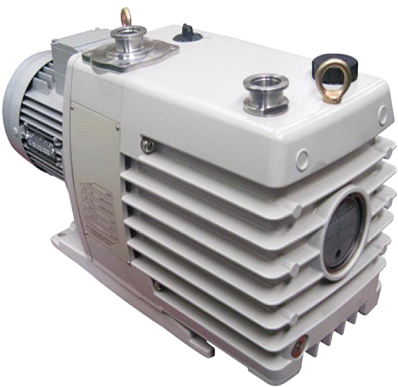

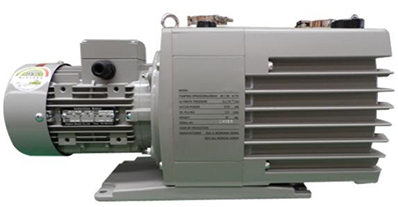

design features

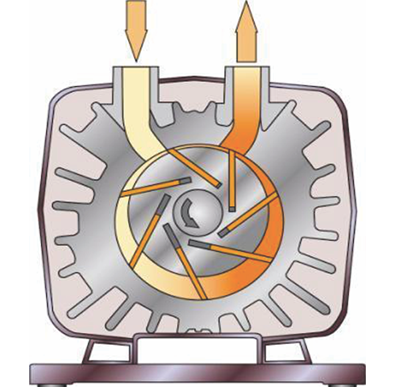

Excellent ultimate vacuum and pumping speed by using high performance new materials. Improved oil anti-suckback system to protect the vacuum system in the event of sudden stop. Occupying strong and constant pressured oil circulating system to protect the pump. Simple maintenance and oil replacement. Simple repair without special tools.