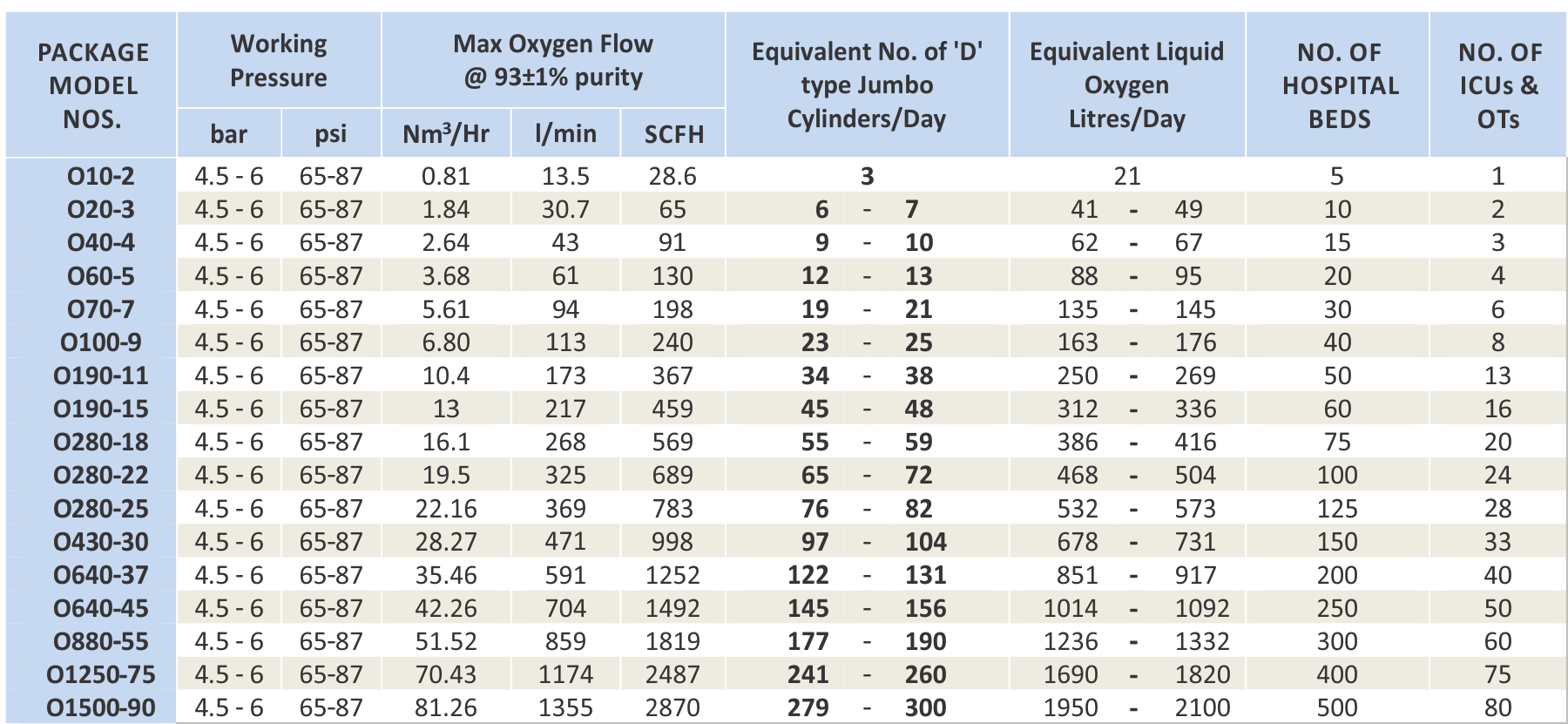

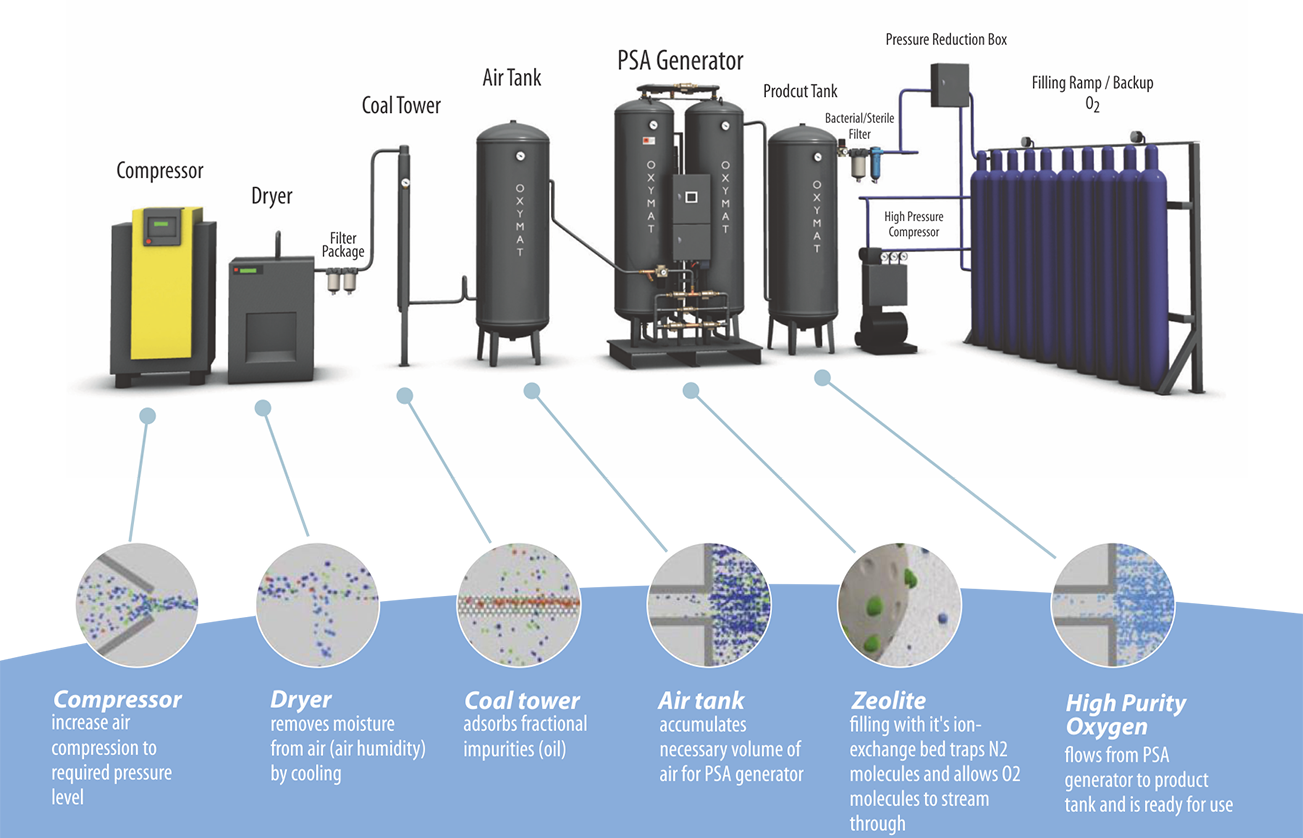

- 24/7 – 365 days continuous on-site generation & consumption. Fully-automatic.

- ECONOMY Reduced oxygen cost.

- SELF RELIANT No more dependency; no risk of supply chain failure.

- The Oxygen Purity meets USP & is monitored in the system

- SAFETY No more explosion or fire hazards.

- NO NEED OF N.O.C.

- Easy to Operate and Maintain.

- Saves Manpower; Reduces Overheads; Prevents Losses

- No more disturbances from noise & movement of bulky O 2 cylinders.