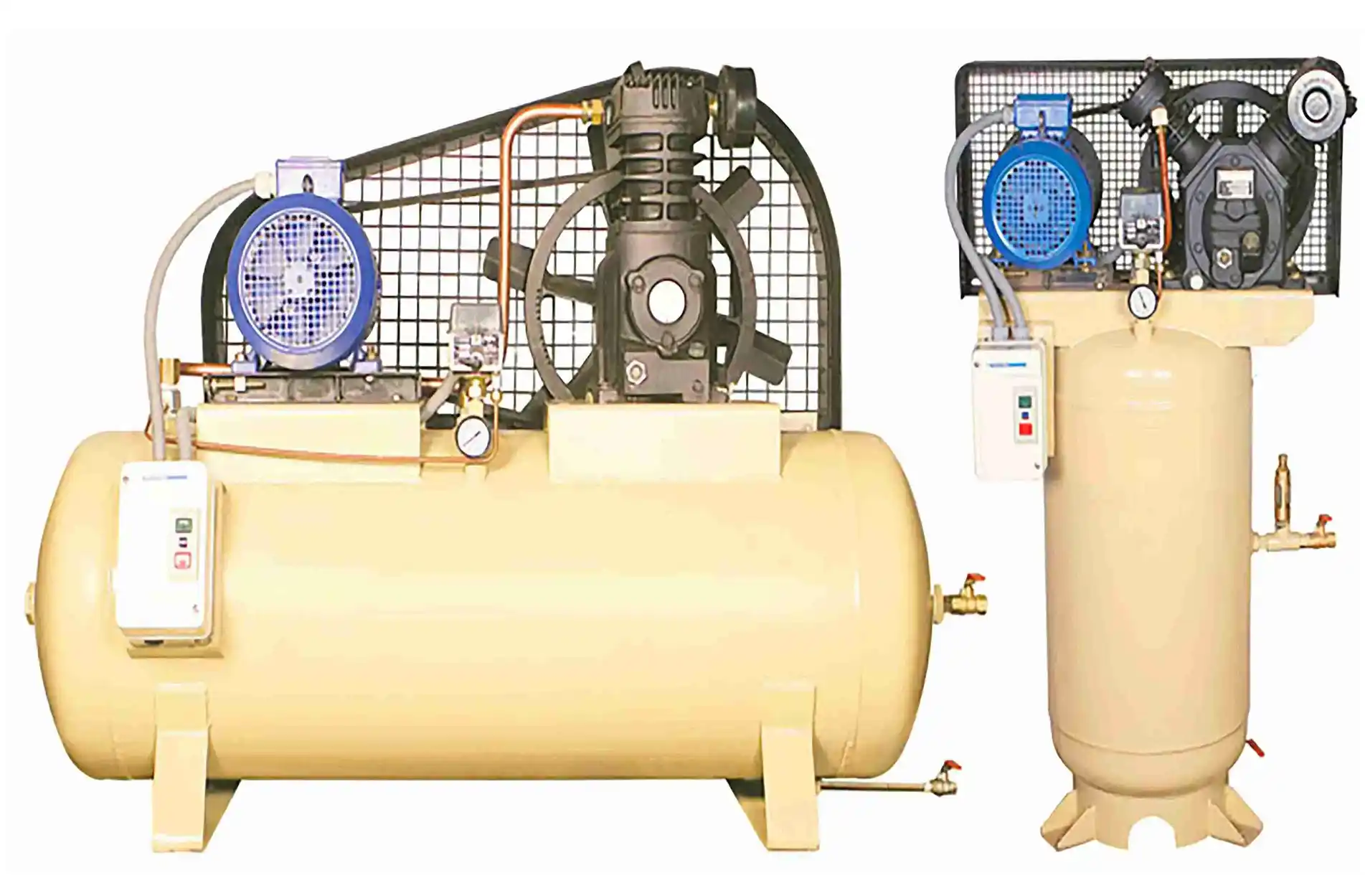

Reciprocating Piston Compressor, also known as reciprocating air compressor is a type of positive displacement compressor where air or gas is compressed by a reciprocating piston inside a cylinder. This mechanical device is widely used in various industries to supply high-pressure air or gas for various applications.

Reciprocating Piston Compressor Components

Reciprocating Piston Compressor Types

Reciprocating Piston Compressors are essential in many industrial processes due to their ability to provide high-pressure air and gas efficiently.

Reciprocating piston compressor Working Principle:

Intake Stroke (Suction):

Compression Stroke:

Discharge Stroke:

Reciprocating Piston Compressor Features:

Reciprocating Piston Compressor Manufacturers in India

Gas Air MultiTech is the best Manufacturer and Supplier of Reciprocating Piston Industrial Air Compressor in India. With years of expertise in the field, we specialize in providing high-quality, reliable, and efficient reciprocating compressors designed to meet diverse industrial needs. Our compressors are known for their durability, versatility, and exceptional performance, making them an ideal choice for various applications, from small-scale operations to high-pressure environments.

At Gas Air MultiTech, we prioritize customer satisfaction by offering a wide range of models that cater to specific requirements, whether you need an oil-lubricated or oil-free variant. Our products are engineered to provide consistent air output, ensuring smooth and uninterrupted operations in your facilities. Additionally, we offer flexible solutions to meet the needs of industries such as manufacturing, automotive, and agriculture.

Our team of experts ensures each unit undergoes strict quality checks and is built to last, minimizing the need for frequent repairs and maintenance. As the top Reciprocating Piston Compressor Manufacturer and Supplier, Gas Air MultiTech delivers unmatched performance, cost-effectiveness, and reliability, making us the preferred choice for businesses across India.

We also specialize in high-performance piston compressors that are designed for heavy-duty operations. Whether you need a compressor reciprocating type for industrial applications or a double piston compressor for enhanced efficiency, we have the right solution for your needs. Our piston air compressors are engineered to provide reliable, consistent performance, ensuring that your systems run smoothly. We also offer double piston air compressors for applications requiring higher air compression output.

Choose Gas Air MultiTech for all your air compression needs, and experience the power of air-powered piston systems designed for superior performance and reliability.